DMG MORI World – Manufacturing the Future

Under the motto "Manufacturing the Future", DMG MORI connects people, technologies and industries. On the occasion of the EMO's 50th anniversary, the company impressively demonstrates how the future of manufacturing is already becoming a reality today. From 22 to 26 September 2025, the innovation leader will be creating DMG MORI World in Hall 2, full of pioneering manufacturing solutions that will sustainably improve life and production – in small, medium-sized and large companies alike. Three focal points characterize the trade fair appearance and form the core of DMG MORI World: Technology, Machining Transformation (MX) and 5+X Industries.

The spotlight here is on the five most important focus industries: Aviation & Space, Mobility, Die & Mold, Medical and Data & Semiconductor. The X connects these and many other branches of industry with the Machining Transformation (MX). More than 40 high-tech machines, including 33 automated manufacturing solutions, cover all common machining processes. Eight of them are world premieres. This shows that technology is increasingly becoming the driving force for change in manufacturing. The second area, Machining Transformation (MX), plays a major role. It paves the way to the manufacturing of the future and is based on Process Integration, Automation, Digital Transformation (DX) and Green Transformation (GX). How the technologies are used in practice can be experienced in the 5+X-Industries area. Lectures on the most important trends in machining complete the exhibition program.

Technology as the driver for transformation

The basic framework for these added values are the innovative technologies that DMG MORI stands for more than ever. They enable small and medium-sized companies as well as industry giants to achieve future-oriented and competitive production. This is due to a holistic product range. In addition to classic machining processes such as milling, turning and grinding, DMG MORI also has technologies such as ULTRASONIC machining and additive manufacturing in powder beds and with powder nozzles in its portfolio – which will be shown live in the DMG MORI World. 33 automation solutions, including pallet handling, driverless transport systems, robotics and intelligent production cells, connect people, machines and technology. The aim is to increase efficiency, conserve resources and enable sustainable progress – for the requirements of today and tomorrow. In close partnership with the certified DMQP partners, who will present their wide range of products, a comprehensive range of solutions is created that specifically expands the machine peripherals.

5+X-Industries as innovation driver for machining

Advanced technologies and the change in manufacturing are becoming visible in real applications for the industry. The X connects these to the Machining Transformation (MX). For many decades, DMG MORI has been at home in the most important industries with innovative products. Aviation & Space, Mobility, Die & Mold, Medical and Data & Semiconductor, as an example, place the highest demands on quality and productivity. Under these challenging conditions, DMG MORI has always developed machining solutions that enable competitive production at all times. Trade visitors to the EMO will see groundbreaking results in industry-specific areas.

Machining Transformation (MX) paves the way

The Machining Transformation (MX) connects all areas of DMG MORI World and redefines industrial value creation. Four strategic pillars form the backbone: Process Integration, Automation, Digital Transformation (DX) and Green Transformation (GX). Each of these pillars addresses key challenges facing the manufacturing industry: productivity, flexibility, and sustainability.

For example, to demonstrate process integration, DMG MORI implements multitasking machines such as the DMC 125 FDS duoBLOCK μPrecision, which will be exhibited at EMO: milling, turning and grinding in a single clamping. Such a solution frees up capacity on other machines and significantly reduces the need for manpower as well as relieves the burden on employees. At the same time, they increase machine utilization to up to 7,000 hours per year. With pallet and workpiece handling as well as robot-based products, DMG MORI offers numerous options for flexible, autonomous production. In an automation area, the machine tool manufacturer will be presenting automated guided vehicles from the AMR series, which handle pallets, workpieces and tools at machining centers and turning machines – including the machines of the NLX, NTX and H-monoBLOCK series.

Digital Transformation (DX) connects the entire production process. In this context, CELOS X from DMG MORI serves as an intuitive, app-based control and operating system that supports users from order planning and programming to process optimization. All machines with CELOS X use the GREENMODE, which reduces the energy and resource consumption of the machines by up to 30 percent. This is a crucial point, because sustainability is an increasingly important competitive factor, which DMG MORI is supporting with the Green Transformation (GX).

New developments for the future of manufacturing

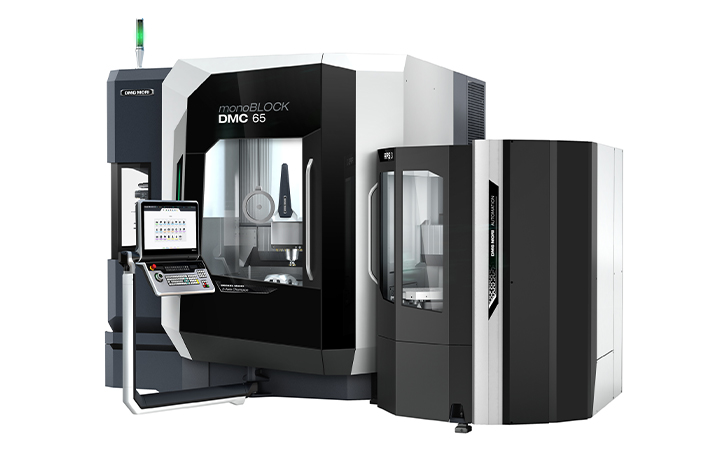

With eight world premieres, DMG MORI is once again taking its product portfolio a big step forward. The latest developments are one hundred percent oriented towards the pillars of Machining Transformation (MX). For example, new models in 5-axis simultaneous machining – the DMC 55 H Twin and the DMC 65 monoBLOCK 2. Generation, as well as the DMU 20 linear 3. Generation – serve as the perfect entry point into complete machining through process integration. The ULTRASONIC 60 Precision goes one step further. It also combines 5-axis milling with ultrasonic-assisted precision machining and offers a positioning accuracy of 4 μm as standard. As the new universal turning machine in the portfolio, the powerful and versatile NLX 2500|1250 2. Generation proves its importance in the context of the Machining Transformation (MX). In addition, thanks to its 2 turn-mill spindles, the NZ DUE TC combines the characteristics of a highly productive production lathe with turn-mill complete machining. In addition, the DMV 200 and SPRINT 420 will be presented as the new machines. Each of these world premieres can be flexibly automated in order to optimally utilize production capacity. The new AMR 1000 supports this area as another driverless transport system for the autonomous handling of tools, material pallets or chip trolleys.

Meeting place for ideas, partnerships and perspectives

The three topics Technology, Machining Transformation (MX) and 5+X Industries reveal what modern production is all about today: it must be adaptable, operate in a resource-saving manner and open up new opportunities for sustainable growth. The presentation of the technologies, the practical focus on the most important industries and the exciting lecture program point to new paths in manufacturing. As a reliable partner, DMG MORI accompanies its customers throughout the entire life cycle – with flexible financing solutions and individual automation retrofits. This offer is complemented by a strong after-sales service: from digital services such as my DMG MORI to exclusive spindle expertise and fast spare parts supply.